-

ashwanisharma95@gmail.com -

View Mobile Number - Send SMS

- Send Email

- GST No. 09AABCO2910M2ZC

Architectural glass

Leading Manufacturers, Exporters, Wholesaler and Retailer of Decorated Glass, Float Glass, Heat Strengthened Glass, Insulated Glass, Laminated Glass and Toughened Glass from Greater Noida.

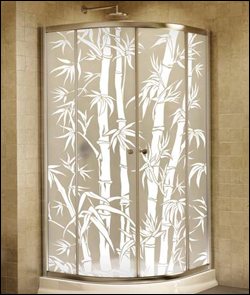

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

Decorated Glass can be used for a number of decorating processes like masking, sand blasting, engraving, etching, grooving, making textures, coloring and staining. We have a team of artists, engravers and computer graphic designers who design the attractive range of Decorative Glasses. The Decorated Glasses, we offer, are extensively used in furniture industry, etc. Our Decorative Glass can be laminated, tempered or double glazed after decoration. We can offer customized Decorative Glasses as per the creative ideas given by buyers.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

We are rated one of the certified Manufacturers and Suppliers of optimum quality Clear Float Glass. We manufacture the Float Glass using high-grade raw materials and well-developed production techniques, in compliance with the requisite industrial standards. Our Float Glass finds wide applications in commercial and residential construction, automotive industry, and has specialty applications such as mirror manufacturing. Owing to clear transparency, high visible light transmission and outstanding quality, Premium Float Glass is highly demanded. Our Float Glass series includes clear float, heavy float, low-iron, and tinted glass. We offer Soda Lime Float Glass as per buyers’ requirements on.

Production Process :

- Float glass is formed from a 'batch' that typically consists of silica sand, soda and lime. At the beginning of the float process, these materials are digitally weighed and mixed with cullet crushed, recycled glass that is left over from previous float cycle.

- Small amounts of other material such as metals and metal oxides may be added to tint the glass.

- Conveyor transfers the batch mixture into the batch house. From there, it is continuously fed into the furnace, where it melts at a temperature of approximately 2400oC.

- From the furnace, the molten glass mixture moves through a canal and onto a pool of liquid tin.

- The speed at which the glass ribbon moves will determine the ultimate thickness of the cooled glass.

- At this point, specialized metallic oxide coatings such as low-emissive or reflective coatings can be applied to the 'atmosphere' surface of the glass, in order to improve its performance or to enhance its appearance. This online coating process is known as chemical vapor deposition and these coatings are called paralytic or 'hard' coats.

- Whenever or not the molten glass is coated, it must be cooled to approximately 1100oF as it progresses through the tin bath, finally reaching a solid state where it is possible to lift it out with the help of rollers.

- The float glass is cooled slowly or 'annealed' in order to remove any residual stresses. After annealing, the solidified ribbon of float glass is cool enough for further processing and cut into pieces.

- Cooled float glass passes through inspection booths to ensure that it has the uncompromising quality needed for its end use. Defects are marked, and the rough edges where knurls pulled the glass through the molten tin are trimmed for use as cullet in a future batch of float glass. The reminder of the glass ribbon is cut for packaging.

- Float glass can be cut into large standard sheets or cut to size, according to its ultimate use. The glass is then inventoried, stored, ready to be shipped.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

We are proud to be one of the famed Manufacturers and Suppliers of Heat Strengthened Glass in Greater Noida, Uttar Pradesh. This glass is preferred over annealed glass of similar thickness and configuration due to its high strength and more resistance to external stresses. Our Toughened Safety Glass is widely used because of additional strength. At our well-developed fabrication unit, Heat Treated Glass is designed in varied specifications using high-performance machinery. Owing to their sturdiness and resistance to mechanical and thermal stress, they are high on demand in the market.

Production Process :

- Heat Strengthened Glass is produced in the same manner as toughened safety glass except that the cooling process is slower.

- During heat strengthening, annealed glass is reheated to a high temperature, and then cooled quickly in a process called “quenching” the resulting heat-strengthened glass is twice as strong as annealed glass of equal thickness and offers significantly greater resistance to wind loads, impacts, and thermal loads.

- The first step in the heat- strengthening process is cleaning annealed glass and cutting to size. Then it is placed in a furnace and heated to approximately 715oC. The glass is then air- cooled to create a balanced condition of stress within the glass itself, making it more resistant to external stresses.

- Heat strengthening does not result in a “safety glass product; heat-strengthened glass breaks in a pattern similar to annealed glass.

Highlights :

- Heat Strengthened Glass is generally twice as strong as annealed glass but still has more resistance to heat fracture and is subject to greater wind load than annealed glass.

- Heat strengthened float glass on its own is not a safety glass but can be laminated to meet requirements.

- When Heat Strengthened Glass breaks, it fragments into larger pieces and tends to stay intact in an opening until replaced. This is particularly useful in high rice spandrel and above ground floor panels because the fragments do not fall into the ground below. Like toughened glass, it cannot be cut, drilled or edge worked. Less visual distortion is also evident when compared to toughened glass.

- Heat-strengthened products form ORO Tuff are perfect for many commercial applications include spandrels, windows in high wind load areas, and applications where the glass is expected to develop high thermal stresses.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Color | Transparent |

| Application | Building Use, Constructional, Residential,Energy Conservation And Management For Domestic And Commercial Purposes |

| Feature | Crack Proof, Fine Finishing |

| Pattern | Plain |

| Type | Insulating Glass |

| Material | Two Or More Glass Panes Separated By An Air Gap |

We bring forth Insulated Glass, which is better way of energy conservation and management. We provide Insulated Glass that is made of two or more glass panes separated by an air gap and edge-sealed together. Our range of Insulating Glass is mostly used for various domestic and commercial purposes and is available in different attractive designs, patterns and sizes as per the specifications mentioned by the buyers.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

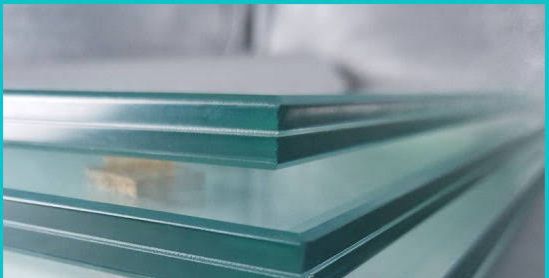

| Shape | Flat |

| Appearance | Transparent |

| Function | Safety Glass |

| Type | Laminated Glass |

| Material | Toughened Glass, Plastic |

| Application | High Tensile Strength, Non-hazardous Shattering |

We are counted among the top Manufacturers and Suppliers of Laminated Glass from Uttar Pradesh, India. Being a quality oriented organization, we assure to provide Laminated Glass that has high tensile strength and offers non-hazardous shattering. Our professionals utilize fine quality of toughened glass and plastic while manufacturing Laminated Glass. Besides, we make available Laminated Glass in various designs and sizes so as to cater to variegated demands of the buyers.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Type | Safety Glass |

| Material | Annealed Glass |

| Color | Transparent |

| Strength | 5 Times Stronger Than Float Glass |

| Application | Glazed Doors, Low-level Windows, Tabletops, Glass Shelving,Door, Sidelights, Shower And Tub Enclosure, Interior Partitions, Storm Doors, Patio-door Assemblies, Stairway Balustrades,Window, Spandrel Areas, Sloped Glazing, Racquetball Courts, Skylights, Sol |

| Feature | Strength, Safety, Resistance To Thermal Breakage |

We manufacture and supply excellent quality Toughened Glass which is reckoned as a safety glass. The Toughened Glass is processed by controlled thermal treatment to increase its strength. Fabricated with utmost precision, our Toughened Glass comes in numerous shapes, sizes, thicknesses and dimensions. It is made from annealed glass that is heated to approximately 650oC and then rapidly cooled. Our Toughened Glass is widely acclaimed for higher thermal strength and ability to withstand high temperature differential up to 250oC. It has excellent light transmission and solar radiant heat properties. Our Toughened Glass is inexpensive to afford. Our Toughened Glass is made through a rigorous heating and cooling procedure that makes it 5 times stronger than float glass. Our Toughed Glass is commonly used for glazed doors, low-level windows (below 800mm) tabletops and glass shelving. In order to retain the reliability and quality of our SafetyToughened Glass , we fabricate them following international quality standards and norms.

Production Process :

- The basic principal employed in the heat-treating process is to create an initial condition of surface and edge compression. This condition of surface and edge compression is achieved by first heating the glass and then cooling the surfaces rapidly.

- This leaves the center glass thickness and then cools; it forces the surfaces and edges into compression.

- In the “heat-treatment” process, the key element is an application of a rapid air quench immediately upon withdrawal of hot (approx.650oC) glass from the “tempering furnace.” The immediate and sustained application of an air quench produces the temper.

- As air direction against hot glass from arrays of fixed, reciprocation or rotating blast nozzles, it is important to extract heat uniformly from both surfaces(uneven heat extraction may produce bow or warp) and to sustains the quench long enough to prevent reheating of the glass surface from the still-hot glass core.

- A quenched condition becomes stable when the glass is reduced to a temperature of approximately 400-600oC.

Applications :

- Toughened Glass is used traditionally in place of other glass products in application requiring increased strength and reduced likelihood of injury in the event of breakage. The building industry, motor vehicle industry and certain manufacturing industries fine Toughened Glass effective and economical in a wide range of application.

- Toughened Glass can also be used for doors, sidelights, shower and tub enclosure, and interior partitions. It is also used in storm doors. Patio-door assemblies and stairway balustrades.

- As a glazing product, it is used in windows and in spandrel areas, sloped glazing, racquetball courts, skylights and solar panels. Manufacturing industries use Toughened Glass in refrigerators, furniture, ovens, shelving, and fireplace screens.

Key Features :

- Strength

- Safety

- Resistance to thermal breakage

Limitations :

- Glass cannot be cut or altered after tempering.

- The raw material used in the manufacturing of Toughened Glass is not free from certain defects, like Nickel Sulfide inclusions, which put it at potential risk of spontaneous breakage.

- Toughened Glass has some roller marks and more distortion than annealed glass.

- Toughened Glass as single glass should not be used for critical applications like overhead glazing where humans may walk.